by LAUREN CODLING

SAFETY standards have improved at garment factories in Bangladesh and more than 300 of them are now “substantially” better five years after the Rana Plaza tragedy, the executive director of a worker’s safety group has revealed.

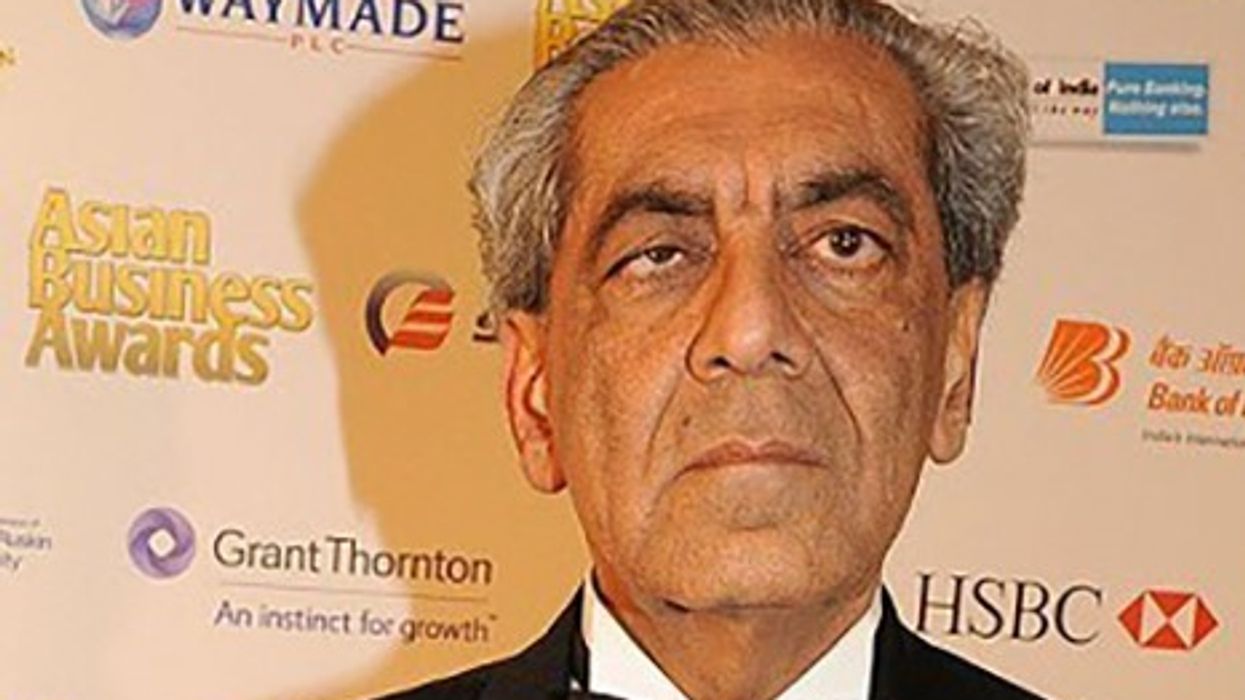

James F Moriarty, executive director of the Alliance for Bangladesh Worker Safety (Alliance), made the announcement in Dhaka earlier this month.

Several Western high street fashion retailers outsource their manufacturing to the south Asian country, where production costs are cheaper compared to those in European nations.

The group of 29 major global retailers was formed after a series of tragedies in Bangladesh’s ready-made garments (RMG) industry, including the Rana Plaza collapse in 2013.

That incident claimed the lives of more than 1,000 people and left 2,000 people injured as the poorly maintained building, housing numerous low-cost clothing companies working for Western brands, collapsed.

In 2015, 38 individuals were charged with murder over the disaster. At present, the trial is delayed by appeals in the higher court.

The tragedy caused worldwide outrage over safety standards for workers in the country’s garment industry, leading to the formation of the Alliance as well as the Accord on Fire and Building Safety in 2013.

Since then, it has made significant changes to ensure the welfare and protection of workers.

“We have 322 factories that have finished substantial completion of all of their physical issues. We will get to 500 sometime this summer – and that will be most of the factories for which the Alliance is responsible,”

Moriarty, who was previously the US ambassador to Bangladesh, told Eastern Eye. “It’s made the factories physically a lot safer.”

The Rana Plaza disaster also triggered demands for Western retailers to help introduce sweeping reforms including new safety inspections and higher wages in the industry, which employs around four million workers.

While Moriarty was in office as the US ambassador, he knew that the garment industry had a lot of positives, such as income and giving job opportunities to women. But he said he was also aware that tragedies were occurring in the sector.

“Sadly, it took a big catalyst [for the Alliance to be set up],” he said. “The eyes of the world focused on Bangladesh after a number of tragedies. It took people concentrating on the problem to actually lead to this kind of progress.”

He added: “It was unfortunate that it took something so tragic [to make a change], but on the other hand, it forced something that would be very unlikely – 29 brands who were fierce competitors saying, ‘if we work together we can drive change’. And that is what has happened.”

Currently, 290 Alliance factories have required structural retrofitting, with 264 of those having fully completed the restructure. Sprinker systems were needed in 141 facilities, of which 118 are understood to have completed installation.

In addition, nearly all factories have upgraded their outdated electrical systems, and most have installed fire doors.

As well as providing physical safety, the Alliance offered employees a means to share their concerns by setting up a worker’s helpline, Amader Kotha, in 2012.

The 24-hour helpline guarantees the workers anonymity and means they can provide feedback to the senior management and the owners of the facilities if there is a problem on the factory floor.

“The helpline is a huge part of our success today,” Moriarty said. “The statistics are amazing – we do get lots and lots of calls. Last month we had around 6,000 phone calls.”

He explained that the calls varied from complaints of abuse from managers to non-payment of wages.

According to Moriarty, 90 per cent of the cases flagged appear to be resolved to the satisfaction of the worker involved and many of the issues are typically fixed within 48 hours of the call being placed.

The Alliance has also set up a mandatory fire safety training programme, which has seen 1.5 million workers across 1,000 factories trained to identify potential safety dangers in their premises and to protect themselves in the event of an emergency.

“We have also trained more than 27,000 security guards in the kind of skills necessary to protect life, rather than property, in the case of an emergency,”

Moriarty added. “We have also trained managers in 17 security guard companies in Bangladesh that provide security services within and beyond the RMG industry.”

The Alliance, which was set up as a five-year project, will now be transitioning to a new organisation in which it will continue to develop a culture of safety within the industry.

On what motivates him, Moriarty said it was the simple fact that 1.5 million workers across the country are “a lot safer than they used to be”.

“We haven’t had anybody in any of our factories die from a structural fire or electrical accident since [the Alliance has] been working in those factories,” he said. “That perfect record might not continue, but it will certainly be a really good one going forward.”